Solving Wiring Issues and Making Safe Splices

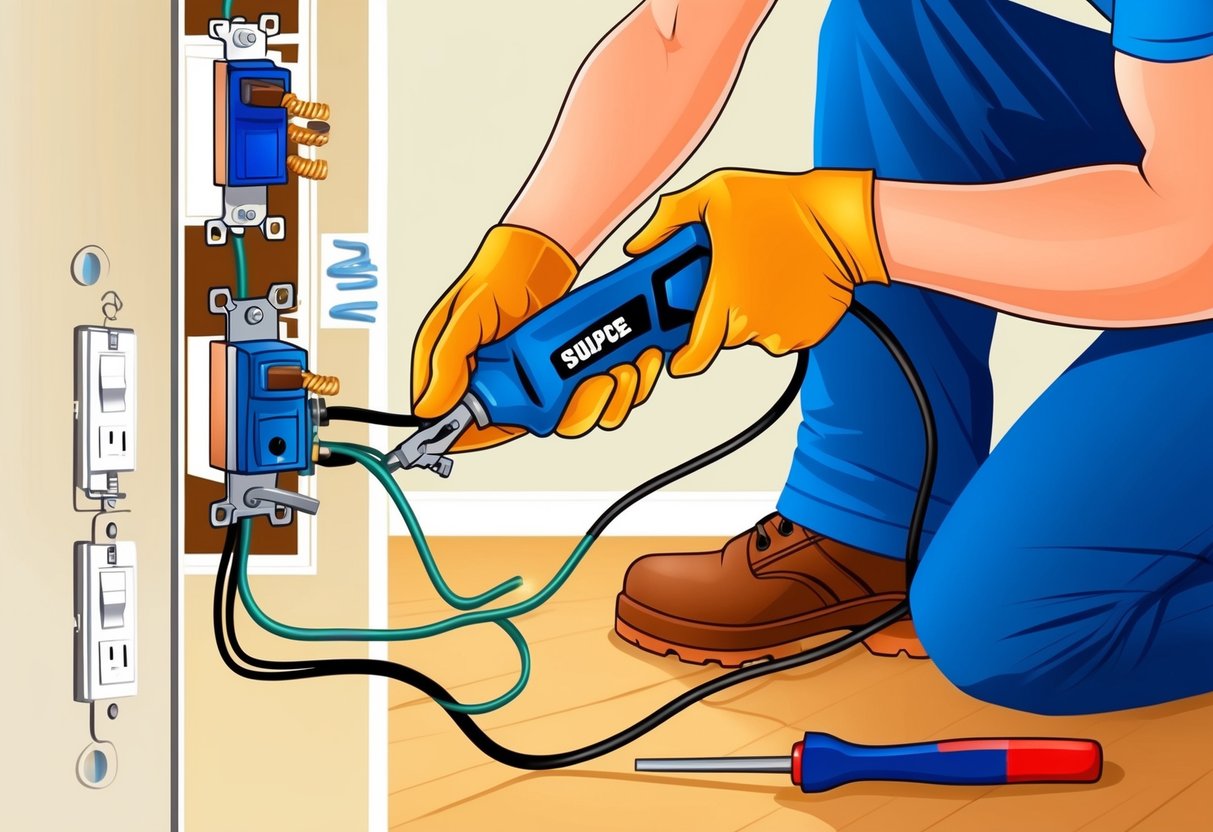

Electrical repairs in the home often require tracing wiring problems, making secure wire splices, and understanding material compatibility. Safety and code compliance are essential to avoid hazards and ensure lasting repairs.

Tracing Faulty or Outdated Wiring

Faulty or outdated wiring may cause outlets, switches, or fixtures to stop working. Visual signs such as discolored outlets, flickering lights, or frequently tripped circuit breakers can indicate underlying electrical wiring issues.

Homes built before the 1980s may still use cloth-insulated or knob-and-tube wiring, which is prone to fraying and is not up to today’s electrical codes. To identify bad wiring, turn off the power at the breaker and carefully inspect for frayed wires, loose connections, or outdated components.

Use a voltage tester to confirm wires are de-energized before working. If multiple outlets or lights stop working, look for a tripped breaker or blown fuse.

Common electrical wiring problems in older homes may require rewiring of specific circuits or entire sections.

Making Secure Wire Connections

A safe splice requires clean, undamaged wire ends and secure connections. Wires should be stripped to the appropriate length—generally 3/4 inch—for ample contact.

For copper wire, use a wire nut or approved connector and twist clockwise to fasten tightly. For better conductivity, wires should be firmly twisted together before securing.

When working in junction boxes, all spliced connections must fit inside a code-approved electrical box. Electrical tape can be used over wire nuts for added security, but is not a substitute for proper connectors.

Never splice wires outside a box or leave connections exposed, as this increases the risk of short circuits and fire. Tutorials for splicing electrical wires can provide step-by-step guidance for homeowners.

Working with Aluminum and Copper Wiring

Homes constructed between the mid-1960s and late 1970s may use aluminum wiring. Aluminum wire is more prone to oxidation and can loosen under thermal expansion, increasing the chance of overheating and fire.

Copper wire is the preferred material today because it resists corrosion and handles current more safely. Connecting aluminum to copper requires special connectors (such as CO/ALR-rated terminals or AlumiConn connectors) to prevent galvanic corrosion.

Never combine aluminum and copper wires directly with a standard wire nut. Always apply an antioxidant compound when terminating aluminum wires in junction boxes.

If a repair or retrofit is needed, electricians recommend replacing aluminum wiring with copper wherever possible for greater long-term reliability.

Preventative Measures for a Safe Electrical System

Proper maintenance, careful observation, and timely action help keep electrical systems reliable and lower the risk of malfunction or hazards. Addressing issues early, scheduling inspections, and installing protective devices can minimize electrical injuries, equipment failures, and costly damage.

Recognizing Warning Signs of Electrical Problems

Early detection of electrical issues greatly reduces the risk of more serious complications. Warning signs such as flickering lights, frequent circuit breaker trips, buzzing sounds, or warm outlets often indicate underlying problems that need attention.

Odd smells, especially those resembling burning plastic, are a signal to unplug devices immediately and seek professional assistance. Loose or damaged wires and discolored outlets suggest overheating, which can precede an electrical fire or shock hazard.

Other warning signs include sparking outlets, persistent power surges, or equipment that malfunctions with no clear reason. Homeowners should keep a checklist to document these symptoms, ensuring nothing is missed when discussing concerns with an electrician.

Importance of Routine Electrical Inspections

Regular electrical inspections are essential for keeping all wiring, outlets, and devices operating within safe limits. During an electrical inspection, professionals check the integrity of cables, functionality of circuit breakers, and the security of electrical connections.

Inspections help identify outdated or degraded components before they fail. A good maintenance schedule for residential spaces is every three to five years, but older properties or those with frequently tripped breakers may need more frequent checks.

Inspections also identify improper DIY work, code violations, and potential fire hazards. Employing a licensed electrician provides peace of mind because they adhere to current codes, use modern diagnostic tools, and offer advice about upgrading to safer technology.

Preventing Electrical Fires and Power Surges

Prevention starts with safe usage and proper equipment. Avoid overloading outlets and always use surge protectors for sensitive electronics to guard against sudden voltage spikes.

Surge protectors absorb excess energy, helping devices survive storms or grid disturbances. For higher-risk environments, consider whole-home surge protection to add another layer of defense.

Reduce fire risks by repairing damaged cords, keeping cords away from water, and replacing worn out or loose outlets promptly. Fire risks rise with neglected issues such as cracked insulation, visible arcing, or persistent overheating.

Routine cleaning around outlets and light fixtures, along with regular replacement of outdated devices, further decreases the odds of a fire. Review manufacturer instructions, and when unsure, consult practical electrical safety tips for homeowners to reinforce safe habits.

If power surges or flickering lights persist, seek professional evaluation to prevent more severe hazards.